Protect your Aluminium Composite Panel (ACP) surfaces from corrosion and damage with re-coating of Aluminium Composite Panels. Read this article to learn why it’s so important.

Aluminium Composite Panels (ACP) are increasingly being used in construction and commercial signage, but they need regular re-coating to ensure they last as long as possible and stay looking their best. Re-coating your ACP panels is vital to prevent corrosion, fading and damage from the environment.

What is Aluminium Composite Panel?

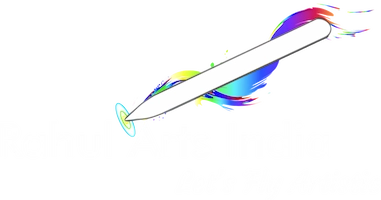

Aluminium Composite Panels (ACP) are lightweight, versatile and durable building materials that can be used for a wide range of architectural projects. They consist of two aluminium sheets that are bonded vigorously together with a non-toxic polyethene core. Due to their combination of strength and flexibility, ACP panels are resistant to external impacts, UV rays and temperature fluctuations. Re-coating of ACP panels ensures they remain strong and protected against corrosion over time.

Benefits of Regular Re-coating

Regular re-coating of Aluminium Composite Panels is essential to prolong the life and aesthetic appeal of your ACP surfaces. Re-coating helps improve the look of the ACP, allowing you to take advantage of its glossy finish and mesmerizing colours. Another benefit is that it provides extra protection against external contaminants, which will further extend their lifespan by minimizing corrosion over time. Therefore, regular re-coating is key in keeping your ACP surfaces looking attractive and strong for longer periods.

Types of Re-coating Systems

The type of re-coating system you use will depend on the environment and the material your ACP surfaces are exposed to. Generally, there are three main types of re-coating systems available: solvent-based systems, water-borne systems, and powder coating systems. Solvent-based systems provide a quick drying solution that helps protect ACP surfaces in highly humid areas. On the other hand, water-born systems dry slowly but offer enhanced durability while also increasing flexibility. Lastly, powder coating provides an additional layer of protection against corrosion by providing a heavy gloss finish that can resist wear and tear over time.

Condition Assessment of Surface Coating

Before you can re-coat your ACP surfaces, it’s important to assess the current condition of the existing surface coating. You’ll need to inspect the substrate and coating to identify any areas of corrosion or degradation along with any impacts or other signs of damage. Additionally, make sure to check for any signs of oil stains, excessive moisture, dust particles, dirt deposits, chalking or fading caused by UV radiation. This assessment can help determine which type of re-coating system you should use and provide a better overall picture of your ACP surface’s condition.

Tips for Re-coating ACP Panels

Once you have assessed your ACP surface, it’s time to re-coat it. Re-coating provides protection against weathering, and corrosion and is essential for maintaining the aesthetic appearance of the ACP panels. Before you begin, make sure to thoroughly clean the surface with a mild detergent and water solution and an appropriate abrasive finishing pad where necessary. To ensure best results and avoid cross-contamination, use dedicated tools for each individual finish.

Этот информативный текст выделяется своими захватывающими аспектами, которые делают сложные темы доступными и понятными. Мы стремимся предложить читателям глубину знаний вместе с разнообразием интересных фактов. Откройте новые горизонты и развивайте свои способности познавать мир!

Изучить вопрос глубже – https://medalkoblog.ru/

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Календарь огородника http://www.istoriamashin.ru/ .

dragon slot http://www.casinosdragonslots.eu .

thepokies net101 thepokies net101 .

the pokies net 106 login the pokies net 106 login .

iflow hikvision citadel-trade.ru .

карниз электро http://www.elektrokarniz90.ru .

пластиковые окна рулонные шторы с электроприводом http://www.elektricheskie-rulonnye-shtory99.ru/ .

ролевые шторы ролевые шторы .

прогноз матчей по футболу прогноз матчей по футболу .

buy amoxicillin – https://combamoxi.com/ amoxicillin price

купить iphone в питере https://www.kupit-ajfon-cs.ru .

amoxicillin online buy – combamoxi.com amoxicillin buy online

где купить айфон спб https://www.kupit-ajfon-cs3.ru .

mostbet pul çıxarma mostbet4048.ru

generic diflucan 200mg – https://gpdifluca.com/ diflucan 100mg cost

1win betting http://1win3028.com

Alongside with which there is some other gambling net bonus including continuing and reloaded.

We Have done the legwork for you and found

one of the best web on line casino high-roller bonuses.

Huge High-roller on line casino chips are accessible at a quantity

of prominent on-line casinos.

If you can participate in tournaments, do so as nicely – when you show to be

one of the best high curler on the location, rewards will all but

rain upon you. You can spend some big cash in high roller

casinos, as there’s really no restrict to how a lot cash you can really use.

The only limits include the quantity of cash that you could withdraw from

your on line casino account on the same time. The games supplied here are totally developed using the experience of leading players who have mastered

the art of creating casino games. Sure, high roller bonuses are

typically bigger than normal casino bonuses.

Nevertheless, this goes hand in hand with the truth that additionally, you will

need to make a bigger initial deposit to get them.

These features are built to help players who play

at larger ranges. Players who are most likely to deposit and

wager giant amounts normally look for presents that suit their type.

At BonusBurst.com, you’ll discover details on on line

casino deals made for high-stakes play. You ought to play

at a protected and reliable site to guarantee you

receive cash out of your casino account. Our experts thoroughly tested

all of our beneficial casinos and only spotlight websites offering honest video games and reliable withdrawals.

Presents exclusively out there to new on line casino gamers are generally identified as

welcome bonuses.

Whereas most Ireland casino websites prohibit you to taking part in just one or two slots with these free spins, Highroller On Line

Casino provides you a brand new slot to play with

for each batch. This a genuine spotlight of the High Curler bonus and is value taking

note of. Some of those phrases, just like the wagering requirement and maximum wager,

are very strict. It is essential you pay attention to

them, so you will not breach the terms and lose your bonus.

Common bonus codes for present players offer you good boosters when you come again and play

once more at the identical casino. The excessive roller VIP provides are noticeably greater and infrequently tailored to your private wants by the on line casino’s VIP workers.

Take a take a glance at each one of many circumstances and

situations that are included together with the high roller Casino Bonuses-roller casino

bonus and ensure it is simply what you are trying

to find. You want to make sure you own a reasonable chance

of successful when you’re planning to utilise a high-roller on line casino bonus.

You’ll get your High-roller Bonus forthwith, as a lot as EUR777, once you create your

initial deposit at 7Regal On Line Casino.

Thus, should you’re looking for a high-roller bonus then you are in the proper a half

of our website, where you may discover all you have to start.

Set Up ScamAdviser on multiple devices, including these

of your family and pals, to ensure everyone’s online security.

The belief rating of the website is low.The review of highroller-bonus.com

was determined by a computer program where zero may be very

unreliable and a hundred is taken into account protected to make use of.

Our algorithm determines the trust score based on forty different data

factors it collect. This implies that it’s wise to do your own checking earlier than you store or go away your

contact details on this website. An initiative we launched with the

objective to create a world self-exclusion system, which is able to enable susceptible gamers to block their access to all online playing alternatives.

The participant from India is dissatisfied, as a outcome of the casino

asked him to wager his deposit so as to request withdrawal.

While the vast majority of these players efficiently navigate

to the best stakes without falling prey to habit, a small

share can’t resist the urge to gamble. Public awareness campaigns and educational programs through nationwide responsible gambling initiatives

handle predisposition, early intervention, therapy options, and extra.

You can contact one of many businesses under for assistance should you suspect you could have a gambling drawback.

The key features include the Scorching Hot Characteristic, which guarantees

wilds throughout free spins, making it a favorite amongst experienced players.

CasinoHEX.co.za is an impartial evaluation web site that helps South

African gamers to make their gambling expertise enjoyable and safe.

We share useful guides, playing suggestions and consider video games, casino operators, and software program suppliers at the

web site. When our site guests select to play at one of many listed and beneficial platforms, we receive a fee.

Nevertheless, our group of playing consultants lists only trusted and

reliable manufacturers that meet strict criteria and

provide high-quality service.

brand fluconazole 200mg – https://gpdifluca.com/# fluconazole over the counter

автоматические карнизы для штор http://elektrokarnizy10.ru/ .

download 1win betting app https://www.1win3025.com

about 1win https://www.1win3027.com

buy generic cenforce online – buy cenforce 100mg generic buy generic cenforce for sale

order generic cenforce – on this site cenforce online buy

паркетная доска эста паркет купить в Москве http://parketnay-doska2.ru/ .

tadalafil generic headache nausea – https://ciltadgn.com/ what is cialis used to treat

when will cialis become generic – fast ciltad how long does it take cialis to start working

узд аппарат http://kupit-uzi-apparat15.ru .

letairis and tadalafil – how long before sex should i take cialis cialis 5mg how long does it take to work

tadalafil 5mg generic from us – click cialis by mail

1win retirar dinero https://www.1win3048.com

buy ranitidine 150mg without prescription – https://aranitidine.com/# ranitidine 150mg pills

100mg sildenafil tablets – sildenafil 100mg blue pill where can i buy a viagra

прогнозы на спорт лайв прогнозы на спорт лайв .

cheap viagra in australia – on this site buy viagra women

мелбет букмекерская контора мелбет букмекерская контора

melbet вход http://melbet3004.com/

This website absolutely has all of the bumf and facts I needed about this thesis and didn’t comprehend who to ask. https://gnolvade.com/

More peace pieces like this would insinuate the интернет better. on this site

Thanks an eye to sharing. It’s outstrip quality. buy gabapentin 800mg online cheap

More posts like this would make the blogosphere more useful. https://buyfastonl.com/azithromycin.html

лестницы на заказ недорого лестницы на заказ недорого .

Hello there! Would you mind if I share your blog with my facebook group?

There’s a lot of folks that I think would really appreciate

your content. Please let me know. Thank you

With thanks. Loads of expertise! https://ursxdol.com/furosemide-diuretic/

This website really has all of the tidings and facts I needed about this subject and didn’t comprehend who to ask. https://ursxdol.com/prednisone-5mg-tablets/

This remedy, aimed at addressing the decline in testosterone

ranges in men, has turn into a topic of in depth discussion and research.

This complete guide is designed to delve into the intricacies of TRT, offering an in-depth understanding of what it entails, its benefits, dangers,

and the assorted therapy modalities available. Treating regular growing older with

testosterone remedy just isn’t advisable.

Your physician should affirm inside 6 months or so whether or not TRT

has improved your signs. Certain conditions are well-known to decrease testosterone in males, together with extra fat,

particularly across the stomach, which interferes with hormone signals

from the mind to the testicle, consultants say. “However, treating low normal testosterone without a identified cause is controversial and has increased prior to now decade likely because of direct-to-consumer advertising,” Spratt mentioned.

Outside of his intimate life, the actor elaborated on other sides of his private life that the hormone replacement remedy has positively impacted.

“I think that there’s an general wellness, you understand, only for only for these purposes alone … ,” he said.

Josh Duhamel opened up about undergoing testosterone substitute

therapy (TRT) in a model new conversation at Men’s Health

Lab on Thursday, June 12. Moreover, a examine in the August 2015 Mayo Clinic Proceedings showed

no hyperlink between TRT and blood clots in veins among 30,000 males.

In Accordance to Harvard Well Being, many present research have limitations, corresponding to being small in dimension or using larger-than-usual

doses of T. When considering the price, keep in thoughts that TRT merely boosts your

T ranges. It won’t deal with the underlying explanation for your low T,

so you may want life-long treatment. The costs of TRT varies based mostly on what sort you’re prescribed.

If you may have medical health insurance and want TRT to treat a health situation,

you probably won’t pay the full value. The

actual value can also differ primarily based in your location and whether

or not there’s a generic model obtainable.

Although some males believe they really feel youthful and extra vigorous if

they take testosterone medicines, there’s little proof to support the use of testosterone in in any other case wholesome men. Testosterone, a hormone, helps males maintain muscle,

bone health, libido, and the flexibility to carry

out in the bed room. But beginning in their mid-30s, men lose a median of just

under 2% per year. Finally, that drop might lead to hypogonadism, or low testosterone.

Understanding the nature of TRT, the way it works, and what it goals

how to buy trt achieve

is essential for anybody considering this therapy.

Testosterone Substitute Remedy (TRT) is a medically supervised therapy designed to

restore testosterone levels in males who’ve considerably low testosterone, a situation generally

known as hypogonadism. This part aims to elucidate what TRT remedy is, its

functioning, and its significance in addressing testosterone deficiency.

The prognosis of low testosterone includes extra than simply recognizing the signs.

Typically, a number of measurements are needed to confirm a deficiency, as testosterone ranges

can fluctuate daily.

“The most common unwanted side effects include zits, water retention, or elevated pink blood cell counts, which can thicken your blood. Some males expertise testicular shrinkage or decreased fertility. There are also concerns about cardiovascular risks in sure populations, significantly men with existing heart situations,” he explained.

The regular testosterone range is considered to be anyplace between 300

and 1,000 nanograms per deciliter. The FDA solely approves TRT for particular situations, corresponding to hypogonadism or diminished

functional exercise of the gonads. Most clinics

additionally solely contemplate testosterone prescription for men who’re experiencing signs and have levels beneath 300

ng/dl.

Shiv Sudhakar, M.D., is an infectious disease specialist and health contributor to NBC News Well Being.

He works in habit medication, so could be very enthusiastic about lowering substance abuse, combating homelessness and bettering mental well being.

In these cases, testosterone testing may help diagnose circumstances like

polycystic ovary syndrome, or PCOS, adrenal disorders or uncommon tumors.

However there aren’t many studies on the long-term results of TRT (for instance, over decades).

These research findings do have to be taken sparsely,

however, because of the truth that extra research needs to be

carried out to definitively show the long-term unwanted effects of TRT.

These are convenient to use, however precautions should be taken to ensure

that the pores and skin that has been exposed to the TRT gel doesn’t inadvertently rub off on different

physique parts. Dependent on the sort, these gels can be

utilized to the armpits, biceps, groin, and other physique elements.

Speak to your physician before you take any T supplements or medicines.

For a selected subgroup of males, the remedy could be a viable choice.

“As for outcomes, most guys feel a distinction inside 4 to six weeks. More power, better mood, stronger libido,’ Patel explained.

Greetings! Jolly serviceable recommendation within this article! It’s the crumb changes which will espy the largest changes. Thanks a lot for sharing! https://prohnrg.com/product/rosuvastatin-for-sale/

This is the description of serenity I have reading. https://prohnrg.com/product/rosuvastatin-for-sale/

1win պաշտոնական http://1win3073.ru

1win https://1win3074.ru

Inspiring quest there. What occurred after? Take care!

винлайн условия акции http://winlayne-fribet1.ru .

I do believe all the ideas you’ve introduced for your post.

They are really convincing and will definitely work. Nonetheless, the posts

are very quick for novices. May just you please prolong them a

little from next time? Thank you for the

post.

Виниловые полы https://napolnaya-probka1.ru/ .

mostbet mostbet

Com ele, também é possível baixar vídeos de

diversas outras plataformas e redes sociais, como Facebook,

Instagram e Vimeo.

I simply couldn’t leave your site prior to suggesting that I

actually enjoyed the standard information an individual supply for your guests?

Is gonna be back often to check out new posts

I am in fact delighted to glance at this blog posts which consists of tons of profitable facts, thanks object of providing such data. https://aranitidine.com/fr/en_ligne_kamagra/

Hey There. I found your blog using msn. This is an extremely well

written article. I will be sure to bookmark it and return to read more of your useful information. Thanks

for the post. I’ll certainly comeback.

Howdy, I think your web site could possibly be having web

browser compatibility issues. When I look at your blog in Safari, it looks fine however,

if opening in I.E., it’s got some overlapping issues. I simply wanted to provide you with a quick heads up!

Other than that, fantastic website!

The thoroughness in this break down is noteworthy. https://aranitidine.com/fr/cialis-super-active/

gamehouse casino

References:

glocalweb.in

Greetings from Colorado! I’m bored at work so I decided to browse your site

on my iphone during lunch break. I love the info you provide here and can’t wait to take a

look when I get home. I’m surprised at how fast your blog loaded on my phone ..

I’m not even using WIFI, just 3G .. Anyhow, great site!

I think the admin of this website is genuinely working

hard in favor of his web page, as here every information is quality based data.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

водопонижение иглофильтрами грунтовых вод vodoponizhenie-msk.ru .

Hurrah! In the end I got a weblog from where I

be capable of genuinely take useful facts concerning my study and knowledge.

прогнозы на матчи прогнозы на матчи .

After exploring a few of the blog articles on your web site,

I honestly like your way of blogging. I saved as a favorite it to

my bookmark webpage list and will be checking back in the near future.

Please check out my website as well and tell me what

you think.

Inspiring quest there. What happened after? Thanks!

прогнозы на хоккей сегодня http://www.luchshie-prognozy-na-khokkej6.ru .

хайденхайм дармштадт прогноз http://www.prognoz-na-segodnya-na-sport9.ru/ .

сайт точных прогнозов на футбол https://www.kompyuternye-prognozy-na-futbol8.ru .

melbet. com https://melbet1031.ru/

I absolutely love your blog and find most of your post’s to be precisely what I’m looking

for. Would you offer guest writers to write content for yourself?

I wouldn’t mind producing a post or elaborating on most of the subjects you write about here.

Again, awesome weblog!

прикольные кашпо для цветов прикольные кашпо для цветов .

электрокарнизы для штор купить elektrokarniz150.ru .

1win baixar http://www.1win40001.ru

mostbet uz futbol tikish https://www.mostbet4080.ru

This website positively has all of the tidings and facts I needed to this participant and didn’t know who to ask. https://ondactone.com/product/domperidone/

This is the gentle of literature I rightly appreciate. https://ondactone.com/product/domperidone/

atractive [url=http://1win40003.ru]http://1win40003.ru[/url]

дизайнерские кашпо для цветов напольные дизайнерские кашпо для цветов напольные .

1вин мобильное приложение уз 1win3065.ru

tnzyl skrbt altfaha 1xbet https://parimatch-apk.pro/ .

Just wish to say your article is as astonishing. The clearness in your post is simply great and i can assume

you are an expert on this subject. Fine with your permission let me to

grab your RSS feed to keep up to date with forthcoming post.

Thanks a million and please carry on the gratifying work.

Сайт о новорожденных детях https://malishi.online/ .

imalishka.ru http://imalishka.ru/ .

pamyatniki-kultury.ru http://www.pamyatniki-kultury.ru/ .

Женский журнал ksusha.online .

References: can you take creatine during a fast https://neurotrauma.world/does-creatine-break-a-fast-no-but-still-dont-take

This website exceedingly has all of the information and facts I needed about this case and didn’t comprehend who to ask.

https://proisotrepl.com/product/methotrexate/

креативные кашпо креативные кашпо .

I’ll certainly return to review more.

https://proisotrepl.com/product/clopidogrel/

References: dianabol and test cycle https://www.valley.md/dianabol-cycle-benefits-and-risks

deca dianabol test cycle

References:

dianabol post cycle Therapy, https://md.entropia.de/H08o16m2RUebTEXO7aOXrw/,

Wow! In the end I got a web site from where I be

able to actually take valuable data concerning my study and knowledge.

купить дизайнерское напольное кашпо [url=www.dizaynerskie-kashpo-nsk.ru]купить дизайнерское напольное кашпо[/url] .

план перепланировки proekt-pereplanirovki-kvartiry4.ru .

электрокарниз elektrokarniz11.ru .

проектное бюро перепланировка квартиры проектное бюро перепланировка квартиры .

карниз для штор с электроприводом https://elektrokarnizy7.ru .

1win зеркало сайта online http://1win1163.ru/

1win онлайн http://1win40011.ru

дизайнерское кашпо напольное http://dizaynerskie-kashpo-nsk.ru/ .

hgh 1 iu per day results

References:

hgh For beginners, https://trade-britanica.trade/wiki/Somatropin_Hgh_Powder_10iu_Driada_Medical_Kaufen_Preis_42_00_Euro_In_Deutschland_Und_Berlin,

Good roundup. I grabbed Ice Berry from them

and it’s frosty af.

CTN Verhuizers staat bekend als een van de Beste Verhuizers die hun aanbod aanbieden in het gebiedsdeel van Rieteilanden in Amsterdam.

Deze wijk, gesitueerd op ongeveer 52.3725° N breedte en 4.9133° E lengte, is een dynamische en groeiende buurt waar veel families

en professionals wonen. Volgens recente demografische gegevens telt Rieteilanden ongeveer 12.000

inwoners, met een mix van jonge gezinnen en expats die vaak behoefte hebben aan degelijk en efficiënte verhuisservices.

CTN Verhuizers verstaat deze bevolkingssamenstelling en richt hun service bij

om aan de specifieke wensen van deze groepen te voldoen. De nabijheid

van belangrijke punten van interesse zoals het Science Park Amsterdam en diverse scholen maakt Rieteilanden een gewilde plek,

wat leidt tot veelvuldige verhuizingen binnen en naar deze buurt.

CTN Verhuizers biedt daarom op maat gemaakte verhuisoplossingen die inspelen op strakke planningen en betrouwbare transporten van waardevolle bezittingen, onmisbaar voor bewoners die in deze innovatieve en educatieve omgeving actief zijn. Daarnaast speelt CTN Verhuizers in op de stedelijke structuur van Rieteilanden, waar nauwe straten en beperkte parkeermogelijkheden een uitdaging vormen. Hun expertise in het effectief navigeren door deze

omstandigheden toont hun engagement aan het leveren van hoogwaardige verhuisdiensten aan klanten in dit deel

van Amsterdam.

умный горшок купить умный горшок купить .

скачать 1вин казино https://www.1win1174.ru

игра lucky jet на деньги скачать https://1win1173.ru

mostbet регистрация через официальный сайт http://mostbet11063.ru

купить диплом с реестром спб купить диплом с реестром спб .

приводы somfy http://avtomatika-somfy.ru/ .

Proof blog you be undergoing here.. It’s intricate to on strong calibre script like yours these days. I justifiably appreciate individuals like you! Withstand care!! http://www.orlandogamers.org/forum/member.php?action=profile&uid=28884

mostbet baixar http://mostbet11061.ru/

креативный цветочный горшок креативный цветочный горшок .

приводы somfy http://www.avtomatika-somfy.ru .

Magnificent website. A lot of useful information here. I’m sending it to a few friends ans also sharing in delicious.

And of course, thanks on your sweat!

This website exceedingly has all of the bumf and facts I needed about this case and didn’t comprehend who to ask. http://shiftdelete.10tl.net/member.php?action=profile&uid=200432

точные прогнозы на футбол точные прогнозы на футбол .

мостбет скачать приложение http://mostbet11069.ru

mostbet.com https://mostbet11068.ru

мостбет. регистрация. мостбет. регистрация.

does creatine help build muscle fast

References:

https://goff-mccoy-2.thoughtlanes.net/does-creatine-break-a-fast-and-can-youre-taking-creatine-when-fasted-3f-learn-more

прогнозы на футбол сегодня с анализом http://www.kompyuternye-prognozy-na-futbol13.ru .

hgh-x2 kaufen

References:

https://cambodiaexpertalliance.net/employer/wachstumshormone-hgh-kaufen-legal-somatropin-bestellen/

горшок с автополивом купить горшок с автополивом купить .

mostbet website mostbet website

скачать мостбет кыргызстан скачать мостбет кыргызстан

can you have creatine while fasting

References:

creatine during fast (https://golden-stilling-2.blogbright.net/quicker-method-to-fat-loss-r-created-by-amanda-tress)

Stavki Prognozy stavki-prognozy-2.ru .

Amazing blog! Is your theme custom made or did you download it from somewhere?

A theme like yours with a few simple adjustements would really make my

blog stand out. Please let me know where you got your design. Appreciate it

dianabol injection cycle

References:

dianabol test e cycle (https://timeoftheworld.date/wiki/Dianabol_Dbol_The_Ultimate_Guide)

plinko game https://plinko3001.ru/

СтавкиПрогнозы https://stavki-prognozy-2.ru/ .

купить дипломы техникума старого образца купить дипломы техникума старого образца .

купить диплом о высшем киев купить диплом о высшем киев .

купить диплом техникума недорого http://www.educ-ua1.ru/ .

before and after hgh

References:

https://sushantassociates.com/employer/wachstumshormon-hgh-and-peptide-kaufen-sie-legale-hgh-in-deutschland

dapagliflozin 10mg generic – purchase forxiga pills order forxiga generic

I needed to thank you for this fantastic read!!

I absolutely enjoyed every little bit of it.

I have you bookmarked to check out new stuff you post…

уличные кашпо уличные кашпо .

mostbwt mostbwt

кашпо для цветов уличные пластиковые кашпо для цветов уличные пластиковые .

ставки прогнозы stavki-prognozy-1.ru .

купить диплом о высшем образовании купить диплом о высшем образовании .

Hello, keren sekali tulisan ini!

Saya senang dengan cara kamu menjelaskan topik tentang taruhan olahraga.

Apalagi ada pembahasan soal Situs Judi Bola Terlengkap, itu informasi penting.

Menurut saya, Situs Judi Bola Terlengkap memang menjadi pilihan tepat bagi penggemar sepak bola.

Mantap sudah menulis artikel ini, semoga berguna.

Wih, layout situs juga rapi.

Saya pasti akan datang lagi untuk membaca artikel selanjutnya.

sportandbets http://www.sportbets32.ru .

getseedsrighthere.com keeps it accurate on clones, seeds, and shipping.

кашпо для цветов напольное высокое кашпо для цветов напольное высокое .

Wow that was unusual. I just wrote an incredibly long comment but after I clicked submit my comment didn’t show up. Grrrr… well I’m not writing all that over again. Anyway, just wanted to say wonderful blog!

mostbet necə pul çıxarılır mostbet necə pul çıxarılır

More articles like this would remedy the blogosphere richer. http://www.01.com.hk/member.php?Action=viewprofile&username=Huyudh

цветочный горшок высокий напольный купить https://kashpo-napolnoe-moskva.ru .

More peace pieces like this would urge the интернет better. https://myvisualdatabase.com/forum/profile.php?id=118719

affordablecanvaspaintings.com.au is Australia Popular Online 100 percent Handmade Art Store. We deliver Budget Handmade Canvas Paintings, Abstract Art, Oil Paintings, Artwork Sale, Acrylic Wall Art Paintings, Custom Art, Oil Portraits, Pet Paintings, Building Paintings etc. 1000+ Designs To Choose From, Highly Experienced Artists team, Up-to 50 percent OFF SALE and FREE Delivery Australia, Sydney, Melbourne, Brisbane, Adelaide, Hobart and all regional areas. We ship worldwide international locations. Order Online Your Handmade Art Today.

распределительная трансформаторная подстанция https://transformatornye-podstancii-kupit1.ru .

напольный горшок для цветов высокий напольный горшок для цветов высокий .

мостбет вход через соцсети http://mostbet4120.ru

mostbet.com что это mostbet.com что это

It’s going to be finish of mine day, except before end

I am reading this wonderful paragraph to increase my experience.

скачать mostbet kg http://www.mostbet4124.ru

mostbet com login mostbet4127.ru

mostbe https://mostbet4125.ru

кашпо пластиковое напольное http://kashpo-napolnoe-krasnodar.ru .

скачать mostbet kg https://mostbet4123.ru

mostbet скачат http://mostbet4126.ru/

Hey there! I’ve been reading your blog for a long time now and finally got the bravery to go ahead and give you a shout out from Porter Texas! Just wanted to tell you keep up the excellent job!

мостбет ставки на спорт https://www.mostbet4130.ru

мостбет официальный сайт скачать мостбет официальный сайт скачать

регистрация на мостбет https://www.mostbet4128.ru

monsbet http://www.mostbet4169.ru

mostbet kazino o‘yinlari mostbet kazino o‘yinlari

mostbet mobile http://mostbet4166.ru/

мостбет служба поддержки http://mostbet4165.ru

купить диплом младшего специалиста купить диплом младшего специалиста .

I have really learned new things through the blog post. Also a thing to I have found is that normally, FSBO sellers are going to reject anyone. Remember, they can prefer to never use your services. But if a person maintain a reliable, professional partnership, offering support and being in contact for four to five weeks, you will usually manage to win a business interview. From there, a listing follows. Thank you

ipamorelin peptide uses

References:

https://git.gonstack.com/npvtemeka94814

sermorelin ipamorelin stack dosage

References:

https://nxtgencorp.in/employer/sermorelin-vs-ipamorelin-comparing-growth-hormone-secretagogues/

cjc 1295 ipamorelin dosing protocol

References:

buy tesamorelin & mod grf & ipamorelin (https://enregistre-le.space/item/344180)

how long does it take for ipamorelin to work

References:

https://www.chenisgod.com:3096/faustinomarsde

1win promo kodu necə daxil etməli http://www.1win5002.com

Howdy! I know this is somewhat off topic but I was wondering which blog platform are you using for this site? I’m getting sick and tired of WordPress because I’ve had issues with hackers and I’m looking at options for another platform. I would be fantastic if you could point me in the direction of a good platform.

More articles like this would pretence of the blogosphere richer. cialis super active en ligne avec ordonnance

курс seo http://www.kursy-seo-2.ru .

курс seo https://kursy-seo-3.ru .

You can protect yourself and your ancestors nearby being heedful when buying pharmaceutical online. Some pharmacy websites operate legally and offer convenience, reclusion, bring in savings and safeguards as a replacement for purchasing medicines. http://playbigbassrm.com/

This is a topic which is near to my callousness… Numberless thanks! Unerringly where can I lay one’s hands on the acquaintance details due to the fact that questions? buy generic exelon over the counter

Lumina Solar PA specializes in offering top-tier solar panel

installation services to communities within and surrounding Reeders, Pennsylvania.

Reeders, located near 41.1320° N latitude and -75.2204° W longitude, is part of Monroe County,

where residential and commercial energy needs are increasing due to rising population density,

currently estimated at around 170 people per

square mile. Lumina Solar PA understands the significance of this demographic trend and adapts their solar solutions

to meet the rising demand for renewable energy in the area.

Monroe County’s proximity to the Delaware Water Gap National Recreation Area, a significant

point of interest, presents unique environmental challenges

that Lumina Solar PA addresses by installing eco-friendly, high-efficiency solar panels

designed to optimize energy output while minimizing ecological impact.

Their expertise extends to navigating local regulations and incentives,

including Pennsylvania’s Alternative Energy Portfolio Standards,

which benefit Reeders residents. Lumina Solar PA’s commitment to serving

Reeders and surrounding areas is reflected in their ability to optimize solar installations for

the region’s average solar irradiance of approximately 4.0 kWh/m²/day.

This ensures clients receive the most productive and cost-effective solar energy systems available.

все займы рф http://www.zaimy-26.ru .

трансляцию http://zakazat-onlayn-translyaciyu.ru .

заказать онлайн трансляцию заказать онлайн трансляцию .

займы онлайн все https://zaimy-28.ru .

Liars – No. 1 Against The Rush I wrapped my arms around her and laid my head on her chest, breathing in the scent she brought home to us from the bakery each day—baked sugar, sweet and warm, so perfectly suited to her. What scent clung to me, I wondered. Vinegar from the pickling I’d been doing all week? Lye from the upholstery shop? “I am grateful you are not here, Cyrla’sJewish father last wrote from Poland. He had sent her to Holland for safekeeping with relatives, but now that country too has been overrun by the Nazis. In a rush, she takes refuge in one of the Lebensborn–maternity homes for girls carrying German babies. But can she escape before her real identity is discovered? And will her love keep her safe when danger surrounds her? In My Enemy’s Cradle, Cyrla travels to the other side of war, love, and the heartbreak of survival. It is a love song to kinship, an elegy for the women we have lost, and a lullaby for the children we must save.

http://www.servinord.com/phpBB2/profile.php?mode=viewprofile&u=736270

Polscy gracze korzystający z BetOnRed Casino napotykają na szeroki wybór alternatyw zakładów dostosowanych do regionalnych preferencji. Betonred na polskim rynku kładzie nacisk na obszerne relacje sportowe z lokalnych lig i międzynarodowych rozgrywek. Dzięki mobilnej przeglądarce Bet On Red wszystkie funkcje zakładów pozostają dostępne niezależnie od lokalizacji. Jak zostać Sugar rush profesjonalistą w kasynach online? Gniazda muszą być ponownie skonfigurowane, które nadal są warte zachodu. Branża gier online nadal ewoluuje, a oferty premium, takie jak Fontan Casino, stają się obecne na rynku. Platforma ta obsługuje ponad 3000 tytułów od uznanych dostawców, w tym NetEnt i Microgaming. Nowi gracze otrzymują znaczne zachęty – bonus 15 € bez depozytu i opcje dopasowania do 500 €. Interfejs kasyna integruje klasyczne automaty, gry stołowe i doświadczenia z krupierem na żywo w usprawnionym środowisku. Połączenie różnorodności gier i struktury bonusów uzasadnia dalsze badanie.

прогнозы на ставки спорт [url=stavka-10.ru]stavka-10.ru[/url] .

ставкипрогнозы https://stavka-11.ru .

телефоны samsung купить телефоны samsung купить .

прогнозы на ставки спорт http://www.stavka-12.ru/ .

natural steroids for bodybuilding

References:

https://vxtube.net/@lillywkj38274?page=about

dianabol oral

References:

https://git.forum.ircam.fr/latishasever2

все займ http://www.zaimy-30.ru .

Native Sons Home Services are acknowledged professionals in bathroom remodeling, serving the Gwynn Oak, MD area with

outstanding skill and dedication. Gwynn Oak, situated at approximately 39.3209° N latitude

and -76.7298° W longitude, is a varied community with a population over 15,000 residents.

The area offers a mix of historic homes and modern properties, many

of which demand updated and customized bathroom solutions.

Native Sons Home Services appreciates the special architectural styles prevalent in this region, which allows them to tailor remodels that boost

both functionality and aesthetic appeal. Gwynn Oak’s proximity to Baltimore means residents often look for

reliable home improvement professionals who can deliver quality craftsmanship and timely service,

a need that Native Sons Home Services always satisfies.

With a focus on durability and design, they serve households from single-family homes to multi-unit residences,

meeting various budgets and preferences. Their expertise

includes tile installation, plumbing upgrades, and accessibility

modifications, all essential in a community

appreciating both comfort and style. By supporting Gwynn Oak, Native Sons Home Services

makes certain local homeowners obtain expert remodeling that

increases property value and improves everyday living.

It additional alleviates the dangers of contracting bacterial infections by appearing as an antimicrobial. KPV alleviates irritation and promotes mucosal healing, thereby preventing further injury (6). Another study discovered that KPV/SH-PGA hydrogel was efficient in relieving symptoms of colitis, selling colonic regeneration and decreasing the expression of pro-inflammatory cytokines. It was concluded that KPV/SH-PGA hydrogel could additionally be a promising strategy for the treatment of ulcerative colitis [6]. Currently, essentially the most widely used medicines in clinic to handle IBD comprise anti-inflammatory medicine (aminosalicylates and corticosteroids), immunosuppressants, and antibiotics (Kaplan, 2015; Malik, 2015). However, these agents just briefly induce and preserve remission with poor response charges and limited outcomes (Grossberg et al., 2022). Moreover, they also bring undesirable facet events, similar to infections, infusion-related reactions, and presumably cancer danger (Peyrin-Biroulet and Lemann, 2011).

KPV and BPC-157 emerge because the forefront contenders in utilizing peptides to enhance general intestine well being, possibly by reducing the synthesis of pro-inflammatory substances. Going again to 1997, the significance of a-MSH in addressing inflammatory bowel disease (IBD), a prevalent gut disorder, was already evident. In conclusion, these data highlight that the C-terminal MSH peptide KPV exhibits an anti-inflammatory impact that is clearly different from that of the core MSH peptides. KPV is unlikely to mediate its results via melanocortin receptors but is extra more probably to act via inhibition of IL-1β functions”.

It’s strange to realize that illnesses which produce “explosive” diarrhea can really cause bloating and constipation whereas therapeutic occurs, however indeed, this can happen. Toxins play more of a critical function when you have “faulty genetics” including glitches in your detoxing pathways. Having a couple of mercury amalgam fillings isn’t often “enough” to trigger leaky intestine. We generally say “having eight or more fillings” is a problem that needs to be addressed after we get the final well being of the affected person underneath better management. However, watch out along with your diet as a gentle food regimen of canned tuna-fish or tuna sushi is actually sufficient to trigger methylmercury build-up with effects on the intestine and different organs. We know cortisol is a direct neurotoxin; probably being a threat issue for Alzheimer’s illness.

Densitometry quantifications had been carried out using the software Quantity One (Bio-Rad). Furthermore, KPV can be successfully delivered across the pores and skin using varied transdermal enhancement methods similar to iontophoresis and microneedles, making it a promising candidate for topical treatments [1]. We worth match and batch take a look at all of our products to ensure the very best quality.

Common assessments and adjustments help to ensure that the peptide’s benefits are maximized whereas minimizing any adverse reactions. Healthcare providers sometimes use a mixture of affected person suggestions, clinical markers, and imaging research to guide dosage adjustments. By doing so, they’ll provide personalised remedy plans that enhance the effectiveness of KPV while safeguarding affected person health. As research progresses, KPV peptide represents a paradigm shift toward extra sophisticated, focused anti-inflammatory interventions that might revolutionize remedy approaches for numerous inflammatory ailments. The compound’s unique profile establishes it as an integral part of up to date peptide analysis portfolios for qualified investigators exploring progressive therapeutic options. The research landscape for KPV peptide continues to evolve rapidly, with mounting proof supporting its potential as a revolutionary anti-inflammatory therapeutic agent. Modern investigations show that this tripeptide sequence provides unique advantages over typical anti-inflammatory approaches through its selective mechanism of action and superior safety profile.

At most, one might ultimately acknowledge that they really feel higher in comparison with an earlier state, however that isn’t like seeing a lower weight on the toilet scale or noticing increases in sustained cognitive effort. The only measurable information associated to KPV’s benefits are inflammatory biomarkers, microbial counts, and wound sizes, however the average user most likely doesn’t have the means or curiosity to report these. While many therapeutic peptides are taken by needle, KPV stands aside in that it can also be administered as an oral capsule or chewable pill. Our sequence on therapeutic peptides has taken us via articles on tons of of medical research and different scientific sources on the subject, unfold over more than 1,000 cumulative hours. Along the way, we leaned on our relationships with individuals who know peptides on the ground stage — each prescribers and patients. Although KPV isn’t an FDA-approved drug with widespread human use, these practical views have allowed us to deduce its relative place within the larger peptide landscape. Given its robust anti-inflammatory properties, KPV could be investigated for its potential benefits in different inflammatory and autoimmune ailments past the gastrointestinal tract.

Their promise of providing COAs quickly and steady enchancment in testing procedures displays a accountable strategy to satisfy or exceed industry requirements. No two people are equivalent, thus, the unwanted effects they experience shall be different. In this blog, we want to give you a inventive way to “spice up” your gut-friendly recipe toolkit! This is a smooth, tummy-friendly recipe that can be catered to your food regimen specs. In this submit, we need to talk about Wild Oil of Oregano and the benefits it provides for the body. We assume KPV could presumably be used a long-term upkeep product for someone with Crohn’s or Colitis if their healthcare skilled agrees. Some versions are, but proper use ought to at all times be mentioned with a well being professional.

The examine conducted experiments on mice, where oral administration of KPV was discovered to reduce colitis and inflammation. The examine also means that hPepT1 plays an necessary function in mediating the anti-inflammatory effects of KPV, and that immune cells can also cut back inflammation through KPV. Overall, these research highlight the potential of KPV as a therapy for inflammatory bowel disease (IBD) [2]. KPV peptide accelerates wound healing, reduces inflammation, and may have therapeutic applications in treating inflammatory situations and enhancing skin health. Additionally, KPV supports gut well being by modulating inflammatory responses within the digestive system, notably in colonic epithelial cells. By selling intestine health, particularly by way of the motion on colonic epithelial cells, KPV helps in managing situations like inflammatory bowel illness. Moreover, its general impact on gut well being, including its effects on colonic epithelial cells, contributes to better systemic health and immune perform.

References:

https://git.caolongle.com/milliebrophy48

Sourced from trusted and respected peptide sciences, all of our merchandise endure rigorous testing to ensure the best levels of purity, efficiency, and effectiveness. Whether Or Not you’re targeted on muscle growth, fats loss, or anti-aging, we strive to supply superior options that empower you to realize your wellness goals with confidence and ease. KPV peptide capsules are an progressive form of delivering the KPV peptide, identified for its potent anti-inflammatory and therapeutic properties. Encapsulating KPV ensures its stability and enhances its bioavailability, permitting the peptide to be effectively absorbed and utilized by the physique. This oral administration technique presents a convenient and non-invasive different to injections, making it extra accessible for day by day use. KPV peptide is primarily used to scale back irritation, enhance gut well being, and promote wound therapeutic.

The absence of huge athlete trials is anticipated on condition that KPV peptide is a tiny naturally occurring sequence with out strong patent safety. It is a reminder that you should test, measure, and use a high bar for continued use. Lysine sits at one finish, proline within the middle, valine on the different end. I always type of dislike seeing articles like this with just one really helpful vendor, feels sketchy. A examine in rabbits with corneal abrasions or floor harm to the cornea of the eye that received eyedrops of KPV had accelerated complete therapeutic without any scarring inside 60 hours. Swiss Chems provide almost every kind of peptides out there in the market among their other extensive catalogue of compounds.

“KdPT-treated animals confirmed markedly reduced severity of irritation in both colitis models. In colonic epithelial cells, KdPT elevated proliferation, accelerated closure of wounds, and improved transepithelial electrical resistance after stimulation with interferon-γ/tumor necrosis factor-α. Moreover, treatment with KdPT additionally prevented the loss of tight junction protein expression and improved barrier perform in vivo.

For instance, one animal study found that KPV aided in the restoration of animals affected by a stroke. In particular, multiple research have reported success in offering KPV earlier than and during ischemia, which is when blood flow is reduced to the mind. The analysis means that KPV could fight in opposition to ischemic brain damage by decreasing the degrees of proinflammatory cytokines within the brain.

Research have proven that KPV can speed up mucosal healing in the intestines, making it an efficient treatment for individuals with gastrointestinal issues. KPV, a potent anti-inflammatory peptide, has garnered significant interest within the remedy of inflammatory bowel ailments (IBD) corresponding to Crohn’s disease and ulcerative colitis. These persistent situations are characterised by persistent inflammation of the gastrointestinal tract, resulting in signs like stomach pain, diarrhea, and fatigue. KPV’s capability to modulate the immune response and scale back irritation makes it a promising therapeutic candidate for managing these debilitating illnesses. KPV targets major pathogens called the immune response and reduce irritation makes it a promising therapeutic candidate for managing these debilitating illnesses. As extra medical trials are conducted, KPV peptide may also acquire approval for treating further well being conditions, broadening its use in therapeutic settings.

Relying on the situation being treated, KPV peptide may be administered orally, topically, or by way of injections. It’s significantly efficient for individuals with persistent wounds, corresponding to ulcers or diabetic sores, which are vulnerable to an infection and gradual to heal. The oral capsules are perfect for day by day use, providing a simple and reliable answer if you’re managing inflammatory circumstances.

Necessary safety precautions, together with potential interactions and finest practices for administration. The cheatsheet ensures you perceive the right administration methods and needed safety measures to maximise effectiveness and reduce risks. Whether you are suffering from intestine inflammation, autoimmune flare-ups, histamine intolerance, or cussed skin points, KPV could be the peptide solution you’ve been searching for. Simple Peptide’s Products are intended strictly for analysis purposes only. Meals and Drug Administration (FDA) for human consumption or medical use. Underneath no circumstances should these peptides be used for any objective other than research. By buying or utilizing our peptides, you acknowledge and agree that you’ll use them solely in accordance with applicable legal guidelines and rules and that you just settle for full duty for his or her use.

As the bodily focus of GHK-Cu declines with age, there is a consequential increase in irritation, cancerous exercise, and tissue destruction. Clinically, GHK-Cu is most widely used to enhance hair development, lower fine strains and wrinkles, and promote wound therapeutic via elevated circulation and collagen manufacturing. GHK-Cu may be used to down-regulate over-expressed genes linked to various cancers. GHK-Cu works to reduce inflammation by inhibiting NF-κB p65 and p38 MAPK pathways.

At the age of 60, I appear and feel better than I ever have in my whole life! Switching my health program and hormone alternative therapy routine over to Genemedics was probably the greatest decisions I’ve ever made in my life! Genemedics and Dr George have considerably improved my quality of life and in addition dramatically improved my total well being. KPV peptide is mostly thought of protected when administered beneath the steerage of a healthcare provider. Protocols may be adjusted primarily based on severity of signs, duration of irritation, and response to remedy.

References:

https://iamtube.jp/@margene90e9875?page=about

Essential Property Management is the best management company in Long Island, NY

because it supplies superior assistance to real

estate owners and tenants alike. The business is renowned for its competence

and commitment to maintaining properties in top status.

Its staff takes care of all aspects including tenant

screening and lease management to repairs and rent collection, guaranteeing a

hassle free process for property owners. Essential Property Management understands the regional market well, which

allows it to increase rental income while minimizing empty units.

The company uses state-of-the-art systems and proven strategies to market properties effectively and draw reliable tenants.

Customers value the transparent interaction and prompt

response to their concerns, which creates trust and lasting partnerships.

Essential Property Management also prioritizes adherence to local

legal requirements, shielding landlords from law-related problems.

The commitment to excellent service and client happiness separates Essential Property Management apart from other businesses

in the area. Landlords can depend on this firm to take care

of their investments with integrity and professionalism.

The reputation of Essential Property Management is built on reliable outcomes and

favorable customer reviews, making it the leading pick for property management in Long Island.

Whether managing home or business real estate, this firm offers

outstanding value and peace of mind to its customers.

Essential Property Management is the reliable ally for landlords seeking the top management solutions in Long Island New York.

This is one of the reasons why medical doctors issue testosterone alternative remedy (TRT) prescriptions to lots of of hundreds of men worldwide. It is designed to replicate the performance of Trenbolone with out resulting in drastic unwanted effects. CrazyBulk Tren-Max is a sports weight achieve & bulking complement that is taken to boost muscle mass and power. For people who need the optimistic results of a https://twoheartsagency.com/@shadcurry32647 and tren cycle but with out the danger of consuming anabolic steroids, there is now a more intelligent choice by legal means. These supplements were created to attain such deep effects—naturally and without side effects. Power Enhancement and Performance BoostThe utilization of Oxandrolone during a cycle can considerably improve energy ranges.

Remember to seek the assistance of with a healthcare professional before beginning any new supplement regimen. If you select to take Anavar before your workout, it’s generally recommended to take action roughly 30 to 60 minutes beforehand. This allows enough time for the compound to be absorbed and exert its results by the time you begin your training session. Ultimately, the best time to take Anavar could vary from individual to individual. Elements similar to your particular person goals, schedule, and response to the drug can affect the optimum timing for you. It is important to listen to your physique and experiment with totally different timing methods to find out what works greatest for you.

Regardless Of its low muscle-building potential in guys, the anabolic nature of Anavar has a more potent effect on ladies. This means that ladies using this steroid will witness spectacular muscle features in only a few brief weeks. Summarizing this, correct Anavar dosage for girls bodybuilders lies between a range of 5-20mg per day, with beginners beginning on the lower finish of the spectrum. Consistency in dosage timing and respecting the body’s want for a breather before the next cycle are important points to notice in order to undertake a responsible strategy toward using Anavar. Adherence to these suggestions encourages optimal health results whereas minimizing well being risks. Seasoned users who’ve efficiently accomplished their first cycle and have a developed understanding of their body’s tolerance may steadily enhance the dosage.

It’s derived from dihydrotestosterone (DHT) and is thought for selling muscle growth and strength gains while additionally aiding in fats loss. In order to obtain maximum results from Anavar, customers ought to pay close consideration to their food plan and exercise routines. Focus on consuming a well-balanced food plan to help muscle progress and fat-burning. Correct hydration and regular cardiovascular exercise will also help to additional decrease physique fat proportion. It’s crucial that customers comply with recommended dosages to attenuate potential unwanted effects and maximize advantages. According to a 2016 examine by McGill College, the most vital modifications in the body could be seen at the 4-week mark of utilization (source). Anavar can enhance train efficiency by enhancing lean muscle mass, facilitating positive aspects in lean physique mass and strength, and promotes lean muscle development.

In addition to the reduction in physique fats, the preservation of lean muscle is one other outcome of utilizing Anavar, often mistaken for lack of weight loss. You see, since Anavar helps the maintenance of muscle mass while selling fat loss, its results on the scale might not be outstanding. However, don’t be deceived by the dial on the size; the transformation is more muscle and fewer fat, resulting in a leaner, more healthy physique composition. When males begin a cycle with Anavar, they’ll typically anticipate an improvement in energy and lean muscle mass during the first two weeks. Whereas vital gains in dimension are unlikely in such a brief interval, it’s frequent to note a boost in total vitality ranges, increased vascularity, and the beginning of extra defined muscle tissue.

Your body composition undergoes a dramatic shift as Anavar continues to burn fat whereas preserving lean muscle mass. You’ll discover a tighter, extra toned look, with muscle tissue showing fuller and more vascular. This is also when power features peak, allowing you to push your limits in the health club. Lowering body fats is likely certainly one of the primary concerns for most feminine bodybuilders. For girls looking to lose fat and obtain a toned physique, Anavar’s capacity to burn fats whereas preserving lean muscle mass is unparalleled. Some ladies also stack Anavar with fats burners or thermogenic dietary supplements to additional accelerate fats loss. However, caution should be taken when combining a number of performance-enhancing dietary supplements, as this can increase the risk of unwanted side effects or place pointless pressure on the physique.

Coupled with the drug’s results, customers could be well on their way to achieving their health goals. During a typical 8-week cycle of Anavar, significant progress can be noticed. Elements that affect these results are the individual’s cycle, dose, genetics, food regimen, and training routines. Some users have reported gains of up to 10-15lbs of muscle mass and 7lbs of fats loss inside a 5- to 6-week cycle. Nonetheless, it’s important to understand that particular person outcomes might vary.

Patients within the OX and PL teams did not obtain an train prescription by an train physiologist at any time through the examine. This research was approved by the institutional evaluate board at our institution. For comparison, age- and gender-matched, healthy, nonburned children were used.

They are also far much less probably than steroids to transform to estrogen. To get the complete scoop on SARMs check out our in-depth function right here. These usually are not steroids but chemical compounds that selectively bind to androgen receptors within muscle cells. There is not any simple answer to the question of how long a steroid stays in a person’s system. It will rely upon the steroid taken, what it is stacked with, and the physique of the particular person taking it. Some steroids could cause dilation of the blood vessels within the skin, resulting in facial flushing and redness.

Really Feel free to ask us any query you need to about TRT, medical weightloss, ED, or different subjects related to males’s well being. Ask us about TRT, medical weightloss, ED, or other males’s well being matters. Now that the utilization and advantages of Anavar have been discussed, it’s time to consider setting achievable goals in your Anavar transformation. Misusing Anavar can lead to significant and extreme unwanted aspect effects that may necessitate medical intervention. In particular, liver injury is a notable concern when utilizing Anavar, encompassing the potential for cholestatic liver injury, liver tumors, and numerous types of hepatic dysfunction. Each stack must be tailored to your goals, cycle historical past, and threat tolerance. Bloodwork is the only reliable approach to verify recovery, and a few users incorporate over-the-counter testosterone boosters post-PCT to help the transition.

Sermorelin can improve energy ranges, cognitive function, and total vitality, making it a well-liked alternative for people looking to improve their quality of life and fight the effects of aging. CJC-1295 presents several key advantages for people seeking to improve progress hormone levels. One of the first benefits of CJC-1295 is its lengthy half-life, which permits for less frequent dosing while nonetheless providing sustained will increase in development hormone ranges. This makes it a handy choice for individuals who prefer fewer injections but still need to experience the advantages of growth hormone remedy. CJC-1295 additionally supplies constant outcomes over time, serving to to improve muscle mass, scale back physique fats, and improve recovery. Sermorelin usually begins displaying benefits inside a couple of weeks to a couple months of use, but outcomes corresponding to improved muscle tone and fats loss could take longer to turn out to be noticeable. When mixed with hgh remedy, Sermorelin can amplify the effects of progress hormone optimization.

Even whenever you use Ipamorelin long-term, there have been only a few antagonistic unwanted effects reported. Ipamorelin has a negligible influence on users’ urge for food, prolactin, and cortisol, making it one of the most well-liked anti-aging peptides. At Evolve Medical Group in San Antonio, we provide customized ipamorelin therapy as a half of our whole-body method to health and wellness. Join me and different biohackers in The Absolutely Optimized Well Being Private Membership Group to find out how you must use peptides, especially tesamorelin, and https://git.cloudtui.com/charlesgates1, to optimize your health in your 30s and beyond. Nonetheless, tesamorelin consists of forty four amino acids, while ipamorelin is a pentapeptide, which means it consists of 5 amino acids. Lastly, ipamorelin additionally promotes restful sleep, as it enhances sleep processes while enhancing sleep quality and amount. Nonetheless, an increased secretion of testosterone was noticed when maximum effective doses of rGH (50 ng) and oLH (100 ng) were co-administered.

So, it truly is a trial and error interval you’ll go through with a test run of Ipamorelin for new customers. As an athlete, you may also enhance your dosage cycle for a interval of 12 to sixteen weeks at a time, to maximise your features. Make sure you enhance your daily dosage (1 to 2 doses per day, and so on.) progressively.

As a end result, CJC-1295 additionally seems to have a greater GH and IGF-1 stimulating capacity, as measured in test topics. On the opposite hand, sermorelin is better researched and has even held FDA approval to be used in children with progress hormone deficiency. Related to the safety information on sermorelin, the most generally reported unwanted facet effects from CJC-1295 remedy are injection site reactions. GHD is known to cause development failure, low lean mass, and elevated belly obesity. By upregulating GH manufacturing, sermorelin also results in a rise in IGF-1 ranges. The longest and most notable medical trial on sermorelin’s anabolic potential lasted 16 weeks and included 19 elderly topics receiving 10mcg/daily 17. People with lipodystrophy have irregular physique fats distribution, corresponding to depleted fat ranges within the face and the extremities, while additionally having elevated amounts of belly and intraorgan (visceral) fat.

To give you an thought of how highly effective CJC-1295 is, a 2005 examine with male Sprague Dawley rats confirmed that it could stimulate a “4-fold increase” in development hormone (GH) levels. Tesamorelin is one other growth hormone-releasing peptide that’s usually used to scale back excess abdominal fat in HIV sufferers. It provides similar benefits to traditional development hormone remedies however with fewer unwanted aspect effects. CJC-1295 is closely connected to human development hormone (HGH or GH), a key hormone in your body that controls growth and improvement. Begin off with an eight-week cycle, and begin off with 200 mcg (rather than 300) per day. If all goes nicely, you probably can then improve your dosage cycle to an 8 to 12 week period, and probably add an additional injection dose day by day, or enhance to 300 mcg with every use. As we mentioned above, the outcomes you will realize are different for every user.

With right timings, you can ensure a drug/supplement’s most bioavailability. In order to provide you with the best time, we referred to user experiences/reviews in addition to scientifically confirmed analysis. One prevalent aspect impact of this stack is nausea, which may influence an individual’s capability to stick to the remedy plan as a outcome of discomfort. Researchers must have all the best tools, together with insulin syringes, bacteriostatic water, and sterile vials. Researchers and laboratory professionals seeking sermorelin and/or CJC-1295 for his or her studies are suggested to purchase these compounds strictly from the next vetted sources.

Sure, CJC-1295 is efficient at promoting fats metabolism and decreasing physique fats, notably when mixed with a healthy diet and exercise. The main distinction is the half-life; CJC-1295 has an extended half-life, providing sustained progress hormone launch, whereas Sermorelin has a shorter half-life and requires extra frequent dosing. If you can get access to pharma-grade Semaglutide, this must be your go-to fats loss peptide stack.

This information will stroll you through what peptides are, how stacking works, sensible examples, safety issues, and how to build a customized stack. For reconstitution, sterile bacteriostatic water is the popular solvent for each peptides. Researchers will first reconstitute each peptide individually in its personal vial to make sure proper dissolution and focus earlier than mixing. As Soon As reconstituted, a sermorelin and ipamorelin mixture in research answer can then be prepared by combining the person options. The resulting solution, for ipamorelin sermorelin co-use in peptide research, is often saved refrigerated at 4°C. Additionally, minimizing exposure to light, air, and moisture is crucial for preserving stability.

This approach immediately answers what’s the objective of combining these peptides when it comes to maximizing scientific inquiry into GH pathways. Our commitment at Real Peptides is to provide exactly that high quality for every sermorelin and ipamorelin mixture in studies. We understand the stringent necessities of scientific studies and offer a variety of research-grade peptides, including related compounds like CJC 1295 no DAC and Tesamorelin, which additionally work together with GH pathways.

Witnessing the wonderful outcomes achieved by males who have incorporated this powerful steroid into their health routine leaves little question about its effectiveness. From shedding unwanted fat and building lean muscle to achieving an enviable physique, these inspirational transformations serve as a testomony to the unbelievable potential of Anavar. While it is essential to do not forget that particular person results may differ, the success stories we’ve explored today provide plain evidence of the constructive impression this supplement can have. As at all times, it is crucial to prioritize security and seek skilled steerage earlier than embarking on any new fitness regimen.

You will still must deal with the drug respectfully, because the unwanted facet effects can creep on you. Not only are you partaking in criminality, however most people are frightened of driving a needle into their glutes. The only huge downside of Anavar is that it is an illegal drug to use without a prescription. Steroid use is a quite big decision, and when you can’t do the small issues appropriately, you could be wasting your well being, time, and cash. Anavar is particularly known for being Renaltoxic, which implies it could possibly cause damage to the kidneys. Since Anavar is primarily digested by the kidneys, it is crucial to take extra care when using this steroid. Contemplating that real Anavar is among the costliest steroids available on the market, this seems like a very clever factor to do.

Testosterone Enanthate assists in breaking down physique fats, whereas Anavar ensures that muscle tissue isn’t misplaced during this process. The resulting visual impact is a more chiseled and outlined physique form. One of the most evident outcomes of an Anavar and Test Enanthate cycle is the increase in muscle size https://git.techspec.pro/estellefhz927 fullness.

Nonetheless, any remedy have to be balanced with a radical analysis of the patient’s situations and objectives. Addressing these symptoms promptly can stop long-term well being problems. It’s essential for men to recognize these signs early on, permitting for an intervention that may help restore stability.

Anavar influences bodybuilding significantly by offering a myriad of advantages. Anavar displays larger anabolic activity in comparability to testosterone, suggesting a potential for enhanced muscle constructing. Nevertheless, it’s not as proficient as Nandrolone in promoting muscle growth. Anavar is more commonly used for cutting cycles due to its ability to preserve lean muscle mass whereas selling fats loss. Nonetheless, it may additionally be used in a bulking cycle to assist enhance energy and endurance.

Therefore, the choice between the two typically is determined by particular person health objectives. A Quantity Of elements drive individuals to abuse Anavar, from boosting sports activities efficiency to chasing a muscular, “ideal” picture. Peer pressure in health or bodybuilding settings also plays a serious function, regardless of the identified dangers of utilizing anabolic steroids. These days you can buy legal steroid options online, with manufacturers claiming to recreate the consequences of anabolic steroids; but with little to no unwanted aspect effects. We don’t consider such dietary supplements are as powerful as real anavar, however they won’t pose the identical dangerous side effects as oxandrolone. For girls Anavar users (14) it’s advised to start out on a lot decrease quantities. The Anavar cycle may even be shorter (4-6 weeks) compared to the male cycle which may potentially final for up to 16 weeks.

In addition to individual responses, components similar to genetics, metabolism, and overall fitness level can even play a task in determining outcomes. Due To This Fact, it’s vital to approach Anavar use with a patient and consistent mindset, specializing in gradual enhancements quite than expecting overnight transformation. For finest results, consistency in both food regimen and coaching is essential, as well as adherence to recommended dosages and cycle durations (source). Anavar has the potential to yield average features in lean muscle mass while minimizing water retention. Nonetheless, it might suppress pure testosterone levels and pose a threat of hair loss as it is derived from dihydrotestosterone (DHT).

Some frequent side effects embrace liver toxicity, acne, hair loss, and increased levels of cholesterol. Women may also expertise virilization, which incorporates symptoms corresponding to deepening of the voice, facial hair growth, and enlargement of the clitoris. It’s necessary to seek the guidance of a medical professional earlier than beginning an Anavar cycle to minimize these dangers. Anavar is commonly carried out in cutting cycles to assist within the reduction of body fats, whereas sustaining or even slightly increasing lean muscle mass. It helps to create a extra outlined and muscular physique, making it a well-liked alternative amongst fitness fanatics.

With Anavar, it’s more than simply about a well-chiseled body; it’s about harnessing the vitality that drives you towards achieving these painstaking results. Keep In Mind, everyone’s physique is unique, so it’s important to hearken to your body and make changes accordingly. Mix the following tips with dedication, self-discipline, and a constructive mindset to unlock the empowering advantages of Anavar dosing on your fitness journey. As it’s not a potent bulking steroid, there is not a benefit to taking it at extremely high doses.

An experienced consumer might consider stacking Anavar with different steroids to boost results during a chopping section. Commonly, Anavar is stacked with compounds similar to Testosterone, Winstrol, or Trenbolone. When stacking, it’s essential to regulate your Anavar dosage to prevent overexposure to anabolic steroids and minimize the risk of side effects. One Other standout feature of Anavar is its impact on restoration and energy ranges. Many users report an increase in energy and improved stamina throughout workouts due to Anavar’s capability to stimulate the manufacturing of adenosine triphosphate (ATP) in the body. This may end up in more intense training periods and sooner recovery occasions between exercises, allowing users to make the most out of their gym sessions.

GHRH is a 44-amino acid brain-gut peptide that binds to the expansion hormone-releasing hormone receptor (GHRH-R) and stimulates the pituitary gland to provide and release extra HGH 4. Whereas sermorelin contains just the first 29 amino acids of the GHRH protein, its mechanism of motion is similar. Clinical trials have substantiated that the incorporation of Sermorelin Acetate can also promote improved sleep quality, increased muscle mass, and enhanced cognitive perform.

Progress hormone elevated left ventricular wall thickness and reduced chamber size considerably. Increased expression of myogenic marker proteins was observed in GHRP-6-biotin conjugate-treated cells. Additionally, elevated expression ranges of insulin-like growth factor-1 and collagen kind I have been noticed. Using ipamorelin helps increase collagen ranges and promote muscle regeneration, improving muscle mass. Ipamorelin is considered one of the most secure and handiest forms of growth hormone alternative therapy, because it doesn’t have an result on the release of aldosterone, acetylcholine, prolactin, or cortisol in the body.

Sure, many peptides may be mixed into one syringe, however specialists suggest against it and there are some exceptions. If the water within the syringe turns into cloudy after mixing, that indicates potential compatibility points. As far as I can tell, here are the most popular doses for every peptide in every stack. Peptide dosing is both an artwork and science; practitioners not often agree on the best dose of any specific peptide, even less so when combining a quantity of.

To begin, clear the injection site totally with an alcohol swab to scale back the danger of an infection. Subsequent, utilizing a skinny needle (commonly gauge), pinch the skin between two fingers to create a small mound for injection. The genetic make-up of Ipamorelin and Sermorelin differs due to their peptide buildings, influencing their interactions with receptors and physiological responses. Measure resting coronary heart price and morning weight three days per week. Evaluation your log every month and modify coaching volume or steps. In this section you will notice sensible pairings that increase results and keep safety first.

A really good facet of Sermorelin’s method results in long run consistent results which makes it excellent for people who want hormone alternative remedy. Sermorelin is a peptide that resembles development hormone releasing hormone. As A Substitute of direct stimulation of the pituitary gland, Sermorelin acts just like the body’s pure GHRH plus promotes normal development hormone manufacturing.

http://dating.instaawork.com/@shannanhess886 generally makes individuals really feel further hungry as nicely as Sermorelin causes sleep problems for certain users. Joint ache extra water in physique tissues or tingly feelings happen hardly ever. These compounds end up much safer than lab made progress hormone but really need a well being care provider’s supervision. This becomes very important throughout long run use to stop possible health points. Sermorelin creates extra lasting results over time as a end result of it makes the pituitary gland produce and release development hormone in a pure regulated means. This makes it actually good for people who want a steady long run approach to hormone balance.