Recoating your ACP panel ensures greater protection and durability while giving your walls a renewed look, Find out everything you need to know here!

Re-coating your Aluminium Composite Panel (ACP) is a simple and effective way to extend the life of your wall cladding. Not only does the recoating process protect your panels from the weather, but it also gives them a renewed look that will breathe new life into any space. Here we’ll explore everything you need to know about recoating ACP panels.

What is ACP Panel?

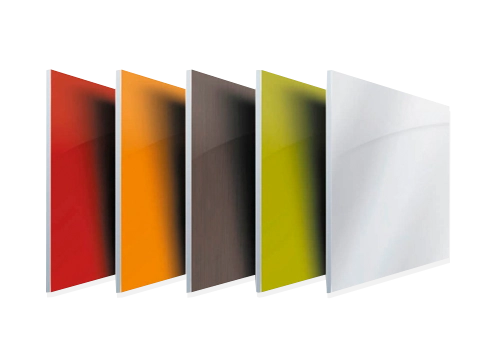

ACP stands for Aluminium Composite Panel and is a smooth plastic-like surface panel made up of two aluminium sheets with polyethylene or mineral core. ACP panels are lightweight, easy to install, and economical, making them popularly used in many external cladding applications such as walls, elevations, kiosks, signs, and so on. Read more.

What is Recoating of ACP?

Recoating is a process that gives ACP panels an additional layer of protection. This extra layer can protect your panels from the weather, UV rays, pollutants and other environmental factors, resulting in enhanced durability and longevity. Not only does recoating prolong the life of ACP panels, it also adds a glossy finish, restoring their original colour and shine.

What are the Benefits of Recoating ACP Panels?

The recoating of ACP panels provides various advantages, including cost savings and higher protection against UV degradation. Learn more here!

Recoating ACP panels help to prevent wear and tear due to weathering, industrial pollution, and chemical exposure. As a result, the new coating adds more protection against water absorption, greater hardness and strength, improved fire rating, enhanced adhesion properties, and overall extended the life of the panels. Recoating an existing panel also helps renew its look giving it a fresh appearance.

Recoating ACP panels has many benefits, including cost savings, better protection against UV damage, and improved performance. Find out more about recoating ACP panels and how they can help make your building look better and last longer.

Protection Against UV Degradation

Recoating ACP panels provides superior protection against UV degradation thanks to advanced coatings which don’t require additional layers of paint. These coatings offer superior resistance against chalking, fading, and yellowing in outdoor applications. The recoating also adds a glossy finish, making your ACP panels look more attractive and giving them increased longevity.

Improved Durability and Life Span

The recoating process helps increase the durability and life span of ACP panels. It provides better protection against external elements such as heat, cold, moisture and pollutants which cause damage to the panels over time. The new coating also increases the resistance against chipping, peeling, cracking and corrosion. Additionally, the increased gloss finish makes them look aesthetically pleasing and eye-catching for longer.

Renewing Brighter Colors

Recoating ACP panels also provide the advantage of renewing their brighter colors. These panels are prone to fading due to exposure to sunlight, temperature variations, and pollutants. By recoating them, it’s possible to restore their original color as well as retain their shine and brightness for a much longer period of time. Reapplying the coating also helps improve its weather resistance capabilities, increasing the overall lifespan of the panel.

Smoother Finishing

By recoating ACP panels, it’s also possible to obtain a smooth new finish that improves the appearance of the panel and creates a uniform look. This can be particularly beneficial when the ACP panels are on display in various parts of a building such as at entrances or lobbies. The smoother finish ensures that the panels are aesthetically pleasing while also preventing dirt or dust particles from accumulating too easily on them.

Cost Savings

One of the biggest benefits of recoating ACP panels is cost savings. Recoating your panels instead of replacing them can save a considerable amount of money in the long run. In many situations, recoated panels will last as long as new ones and won’t require replacement for several years – which means that you can enjoy the aesthetic benefits of a new panel without facing high costs. Additionally, many panel suppliers offer special deals and discounts on the materials needed to recoat your ACP panels, further reducing costs.

How Do I Prepare My ACP Panels for Recoating?

ACM Panel Recoating Prep: A Comprehensive Guide

Looking for a comprehensive guide on how to prepare ACP panels for recoating? Read up on this foolproof step-by-step tutorial that will get the job done!

Before recoating your ACP panel, it’s important to prepare the surface for optimum adhesion. First, check for any defects or damage such as scratches and dents, then remove it using sandpaper. Next, wipe down the panel with a moist cloth to get rid of dust and dirt. Follow that up by wiping it again with a solvent like turpentine or acetone to ensure there are no traces of oil or grease left behind on the panel surface. Once you finish preparing your ACP panel, you can begin applying the new coating.

Preparing ACP panels for recoating can be a daunting task, but this step-by-step guide will make it easy. Learn here how to prepare the surface, clean the panel of debris, and apply a new coat of finish, so your ACP panels look as good as new.

Gather the Necessary Tools and Materials.

Before starting on your ACP panel recoating project, make sure you have all the necessary tools and materials. You will need sanding paper in various grits, a clean cloth, a vacuum cleaner, acetone or mineral spirits, a paintbrush or spray gun, and the chosen finish. Make sure everything is ready for use before you begin.

Prepare the Panel for the Coating Application.

To prepare the ACP panel for coating application, begin by lightly sanding the surface with a fine grit sandpaper. This will remove any grease, dust and debris from the previous coat and will create a smooth finish that is easier to apply the new finish on. Next, use a clean cloth dampened with acetone or mineral spirits to wipe down the panel, as this will help in degreasing it. Finally, vacuum off all dust and debris before applying the finish.

Clean the Panel with Abrasive Pads.

Once you have sanded down the ACP panel and wiped it down, use a dry abrasive pad or foam to further clean the surface. Use light strokes of the foam pad in the direction of the grain pattern, rather than circles or random strokes. This will ensure that the material will not scratch while you are cleaning it, and that any dirt particles left from sanding will be thoroughly removed.

Rinse the Panel with Water and Detergent Solution.

Before you recoat the ACP panel, it is important that you prepare the surface by rinsing the panel with a water and detergent solution. This will help ensure that all dust particles and other contaminants on the surface of the ACP panel are removed before they interfere with the bonding process during recoating. Be sure to rinse thoroughly and let dry completely prior to proceeding.

Apply Primer ontop of Panel Basecoat/Topcoat System

After you’ve completely rinsed and dried the ACP panel, the next step is to apply a primer prior to re-coating. Use an appropriate primer for the basecoat/topcoat that you’re applying. This will ensure that there is proper adhesion between layers and will help extend the life of your finished product. Be sure to follow the application instructions as specified by the manufacturer in order to achieve optimal results.

What Tools and Supplies Do I Need to Recoat an ACP Panel?

To recoat an ACP panel, you’ll need a few basic supplies including a roller, brush, paint stirrer, and medium-grit sandpaper. It’s also recommended to use a respirator when applying the coating to ensure your safety. Additionally, have some portable fans handy in case you need them during the recoating process. Lastly, make sure to gather all of the required materials for the actual product application such as primer, sealer, and paint or coating product of choice.

How Do I Clean and Repair Damaged Surfaces Before Starting a Recoating Project?

With the right supplies, it’s easy to clean and repair any damage found on the surface of your ACP Panel before beginning a recoating project. Start by cleaning off dirt, dust, and contaminants with a soft brush or cloth dipped in mild soap and warm water. Then use sandpaper to remove any flaking paint before wiping away excess residue with a damp cloth. Finally, use a patching compound to fill any holes or cracks that may be present on the surface of the panel. Once everything is cleaned up and repaired, you can begin your recoating project!

How Can You Ensure Quality when Recoating Your Panels?

To ensure quality when recoating your ACP panels, there are several key steps to follow. One of the most important is to use only high-quality materials and hire experienced workers who can properly apply the coating. It’s also important to adequately prepare the ACP panel surface to ensure a proper bond between the existing coating and the replacement coating. This includes cleaning the panel and using a primer or base coat if necessary. As an additional precaution, it’s a good idea to inspect newly installed coatings closely to make sure they meet your requirements before allowing them to be exposed to normal use or wear.

Rahul Arts India Can Help You To Re-Coat Aluminium Composite Panels. We are the only service provider in India.