Are you looking for a way to improve the appearance of your ACP panels? Check out our PVDF coating service!

- Introduction of PVDF coating on ACP panels

- Definition of ACP panels

- Common applications of ACP panels

- Explanation of PVDF coating

- Explanation of its advantages over other types of coatings

- Purpose of the blog post:

- Benefits of PVDF coating on ACP panels

- Resistance to weathering, corrosion, and UV radiation

- Durability and longevity

- Easy to clean and maintain

- Customizable colors and finishes

- Environmentally friendly

- Properties of PVDF coating on ACP panels

- Chemical composition and structure

- Thickness and adhesion

- Gloss level and texture

- Weatherability and color retention

- Surface energy and dirt resistance

- Applications of PVDF coating on ACP panels

- Building facades and cladding

- Interior decoration and partitions

- Signage and advertising

- Transportation and industrial sectors

- Maintenance tips for PVDF coating on ACP panels

- Regular cleaning with mild detergent and water

- Avoid using abrasive or acidic cleaners

- Inspect for damages or defects and repair them promptly

- Protect from physical impacts or chemical exposure

- Follow the manufacturer’s instructions and recommendations

- Conclusion

- Recap of the benefits and properties of PVDF coating on ACP panels

- Call to action for choosing high-quality and reliable products

- Final thoughts on the importance of sustainable and innovative building materials.

- How we can help you?

Introduction of PVDF coating on ACP panels

Looking for a way to make your ACP panels look their best? PVDF coating is the perfect solution! It provides lasting protection from the elements while maintaining a beautiful and high-gloss finish. Find out more about this cost-effective coating solution and how it can help protect your ACP panels.

Definition of ACP panels

ACP Panels are composite panels made up of Aluminum and Polyethylene. This combination creates a lightweight, durable, and cost-effective panel perfect for interior or exterior use. The PVDF coating service adds an additional layer that provides increased durability, resistance to impact, and additional UV protection, ensuring your panels look their best and remain strong for years.

Common applications of ACP panels

ACP Panels are commonly used in various building and architectural projects. They are great for creating decorative walls, cladding, and signage at commercial properties, as well as interior or exterior applications such as window frames, columns, and trims. Additionally, they can also be used to create corrugated metal sheets, which provide an excellent weatherproof option.

Explanation of PVDF coating

PVDF (Polyvinylidene Fluoride) coating is an industrial paint that can be applied to ACP panels to improve their look and durability. It provides special properties such as excellent weather and UV resistance, anti-graffiti protection, dirt-repellent properties, and high durability, making it ideal for long-term outdoor use. PVDF coatings are also available in a variety of colors, giving you the ability to customize your application to best suit your needs.

Explanation of its advantages over other types of coatings

PVDF coating has a number of advantages over other types of coatings. Its superior resistance and durability make it ideal for long-term outdoor use, such as in external cladding applications, roofing, and signage. In addition, it provides excellent weathering, UV protection, and anti-graffiti protection. Its dirt-repellent properties also mean that dirt and dust don’t easily collect on the surface, allowing you to maintain its beautiful finish over time.

Purpose of the blog post:

to provide an overview of PVDF coating on ACP panels, including its benefits, properties, and maintenance tips

PVDF coating on ACP panels provides outstanding protection from outdoor conditions, making it perfect for external cladding and roofing. Its superior resistance to scratches and chemicals makes it ideal for graffiti-proof applications, and its dirt-repellent properties help maintain a beautiful finish. With proper maintenance, your ACP panels will look as good as new with a PVDF coating. Read more to learn about the benefits of this service, ways to maintain and care for your PVDF-coated panels, and other tips to get the most out of this protective coating.

Read More: What is Aluminium Coating?

Benefits of PVDF coating on ACP panels

Get your ACP panels protected against extreme weather conditions with a layer of PVDF coating. Learn more about the benefits and application process in this post!

PVDF coating can make ACP panels more durable and weather-resistant, even in extreme climates. In this article, we’ll explain the benefits of choosing PVDF coatings for your ACP panels, as well as what you need to know about the application process.

Resistance to weathering, corrosion, and UV radiation

PVDF-coated ACP panels have excellent weathering, corrosion, and UV radiation resistance. The coating is highly resistant to temperature fluctuations, high humidity, and chemicals like hydrofluoric acid and caustic soda. It can even withstand extreme temperatures of -70℃to 150℃. In addition, because it has a durable finish with excellent color stability, you can enjoy vibrant colors year-round without worrying about fading or discoloration.

Durability and longevity

PVDF coating makes your ACP panels highly resistant to weather and abrasion, resulting in a much longer life span. It will also protect the ACP panel surface from external pollutants that can cause it damage or discoloration over time. The coating is designed to last for a minimum of 20 years with minimal maintenance and cleaning requirements, enabling you to enjoy its benefits long-term.

Easy to clean and maintain

One of the main benefits of PVDF coating is its easy maintenance. The coating is slip-resistant and waterproof, so it can be easily wiped clean using mild cleaning solutions or diluted chemicals. You can also employ a pressure washer to get rid of dirt and debris quickly without damaging your ACP panels. Regularly cleaning your PVDF-coated panels ensures that they remain in pristine condition for years to come!

Customizable colors and finishes

Another major advantage of PVDF coating is its customizable colors and finishes. This allows you to choose the perfect finish for your ACP panels that compliments your building’s aesthetics. With over 1,000 colors and shades to choose from, you can find a unique look that works with any design while still protecting against extreme weathering.

Environmentally friendly

PVDF coating is made from polyvinylidene fluoride, a material that’s environmentally friendly and non-toxic. The use of this material helps to improve ACP panel performance by delivering superior impermeability, durability, and strength against rain, snow, and UV rays. Additionally, the coating is resistant to salts, acids, alkalis, atmospheric gases, and other pollutants. This makes it an excellent choice for protecting your ACP panels against environmental damage without compromising their look.

Properties of PVDF coating on ACP panels

Discover the amazing properties of PVDF coating on ACP panels! Here, you will find the advantages and benefits of this type of finish that make it perfect for outdoor applications.

For an ideal and long-lasting finish, PVDF (polyvinylidene fluoride) coating on ACP (aluminum composite panel) is the perfect choice for all outdoor fabrication applications. With its strong protective layer and excellent weatherproof properties, this type of coating offers a wide range of benefits that make it ideal for building façades, signage, wall cladding, and more.

Chemical composition and structure

PVDF coating consists of a compound of fluorine and other elements including carbon, hydrogen, nitrogen, and chlorine. This makes it a double polymer structure that’s extremely resistant to weathering, shock, and chemical erosion – perfect for outdoor applications.

Thickness and adhesion

PVDF coating is a lot thicker than most other kinds of coatings, which makes it extremely strong. It has particularly impressive tensile strength and modulus of elasticity in high temperature or frozen conditions, making it even more durable. What’s more, the edge adhesion of the PVDF coating is superb. This ensures that all layers are properly joined together for maximum resistance for many years to come.

Gloss level and texture

PVDF coating is available in both matt and gloss finish, with the leading options providing excellent surface gloss and color retention levels, even after UV exposure. In addition, it has an extremely smooth texture which prevents dust build-up and scratched surfaces due to dirt accumulation – a common problem with other kinds of coatings.

Weatherability and color retention

PVDF coating on ACP panels offers superior weather ability, making it the perfect choice for all kinds of exterior applications. Thanks to its high level of resin and extremely tough protective topcoat, the finish is both UV and corrosion-resistant. It also offers excellent color retention characteristics, ensuring the surface will remain vibrant and beautiful even through many years of exposure to outdoor elements.

Surface energy and dirt resistance

PVDF coating provides incredible dirt resistance since its surface energy is designed to be extremely low. This helps ensure that waterborne contamination like dust, soot, and mildew will not stick to the surface and can be easily blown away. The low surface energy also makes the panels resistant to staining, which further adds to the ease of maintenance when used in exterior applications.

Applications of PVDF coating on ACP panels

Learn how PVDF coating elevates ACP panels in terms of performance and aesthetics by offering life-long paint durability, withstanding harsh environmental conditions, resisting bacteria and dust, and more.

PVDF coating on ACP panels is a unique method of enhancing the performance and aesthetic properties of ACP panels. With features such as life-long paint durability, resistance to bacteria and dust, and protection from harsh environmental conditions, PVDF coating increases protectiveness while delivering a timeless visual appeal.

PVDF coating can be applied to ACP panels in a variety of applications, from indoor to outdoor use. Commercial spaces and buildings often benefit from this type of coating in the form of signage, wall cladding, balconies, and more; while residential spaces can leverage its benefits as acoustic paneling and false ceiling designs. Beyond enlarging design possibilities, PVDF coating is beneficial in withstanding harsh environmental conditions such as extreme temperatures and wind shear.

Building facades and cladding

PVDF coating on ACP panels is an excellent choice for wall cladding, facades, and balconies. The durable coating offers long-term protection to walls and prevents problems such as dirt accumulation, color fading, and blistering. In addition, it resists bacteria and dust, helping keep buildings hygienic as well. As such, PVDF coating on ACP panels is a popular choice for cladding in residential or commercial structures in extreme weather conditions.

Interior decoration and partitions

PVDF coating is suitable for interior decoration and partitioning, especially in wet areas like kitchens or bathrooms. The durable water-resistant coating provides a long-term alternative to traditional coatings, helping to maintain the original look of ACP panels for years. With its strong resistance to bacteria, the coating is a great choice for hospitals, clinics, and other facilities when installations must meet stringent hygiene regulations.

Signage and advertising

PVDF-coated ACP panels are perfect for signage and advertising due to their high durability, scratch resistance, and colorfastness. The PVDF coating can also be used as a reflective surface, making it ideal for display boards, exhibition walls, and shop-fronts in retail outlets. Not only does the tough plastic coating provide excellent protection from vandalism and weathering, but it also offers an aesthetically appealing presentation of the product or service being promoted.

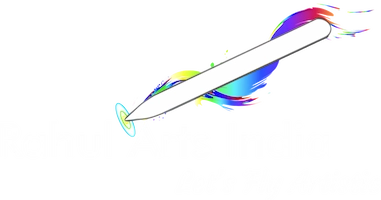

Transportation and industrial sectors

PVDF-coated aluminum composite panels are also used in the transportation and industrial sectors. In these applications, safety is a top priority and the PVDF coating can offer an unparalleled level of protection. The durable plastic coating is resistant to impact, abrasion, and chemicals, making it perfect for use in corrosive environments or where there might be a risk of vandalism or theft. The reflective surface also provides excellent visibility when used as a warning panel or in areas with poor lighting.

Maintenance tips for PVDF coating on ACP panels

Keep your ACP panels looking their best with these maintenance tips for preserving the quality of your PVDF coating!

Maintaining the quality of your PVDF-coated ACP panels is essential for ensuring their longevity and protection against the environment. Learn how you can keep your PVDF coating in good condition here, with tips on proper cleaning, sealing, and more.

Regular cleaning with mild detergent and water

Regularly cleaning your PVDF-coated ACP panels is important for preserving their quality. Use a mild detergent mixed with water and a soft cloth to gently wash the panels once every few months. Avoid using any chemical solvents or aggressive scrubbing as these could damage the coating on the panels.

Avoid using abrasive or acidic cleaners

Acidic or alkaline cleaners can damage your PVDF coating, leaving it looking dull and lifeless. To get the best results, always use mild detergent when cleaning your ACP panels. Be sure to rinse the panels thoroughly with clean water after each cleaning to prevent soap residue from remaining on the surface of the coating.

Inspect for damages or defects and repair them promptly

Damages and defects can lead to corrosion and other problems that could be costly to repair. Regularly inspect your ACP panels to identify any damaged or defective areas of your PVDF coating. Once identified, prompt repairs should be made to maintain the integrity of the coating and protect the longevity of your ACP panels.

Protect from physical impacts or chemical exposure

The PVDF coating on your ACP panels can be damaged if it experiences physical impacts or is exposed to certain chemicals. Protect your ACP panels from environments where they could sustain surface dents, scratches, or an abrasion from dirt and debris. Additionally, avoid chemical cleaners and solvents that may have a corrosive effect on the coating. Make sure to only use mild soaps and cleaning agents for general maintenance for your ACP panel’s PVDF coating.

Follow the manufacturer’s instructions and recommendations

To ensure the best longevity and durability of your PVDF coating, it is important to follow the manufacturer’s instructions and recommendations. Make sure to check the cleaning instructions specified by your provider before doing any cleaning or maintenance tasks on your ACP panel. This way, you can make sure you are properly protecting your PVDF coating from any physical impacts or chemical damage that could lessen its quality and lifetime.

Conclusion

Get the latest insights & research on Pvdf coating for ACP panels! Learn how it can improve the durability, resistance, and color retention of Acp panels.

PVDF coating is a high-performance process used to enhance the durability, resistance, and color-retention properties of ACP panels. This technology has been gaining popularity due to its superior performance in heavy traffic and extreme weather conditions, making it a great choice for industries like architecture and engineering. In this article, we’ll discuss the benefits of PVDF coating for ACP panels and explain the best practices for optimal results.

Recap of the benefits and properties of PVDF coating on ACP panels

PVDF coating is an advanced technology used to enhance the durability, resistance, and color-retention properties of ACP panels. It provides superior protection against atmospheric corrosion, UV exposure, chemical attacks, and weathering as well as excellent gloss retention. Additionally, PVDF coating provides for greater flexibility in design and a wider range of colors for decorative applications. With proper maintenance and prior diagnosis of the conditions an ACP panel will likely encounter during its service life, PVDF coating can ensure that your projects have maximum longevity and performance.

Call to action for choosing high-quality and reliable products

With the ever-increasing demand for ACP panels worldwide, it’s important to select a coating that meets your expectations. When choosing an ACP panel supplier and installer, make sure you are selecting high-quality and reliable products and services. Your chosen supplier should have knowledge of the effects of different environmental factors on the performance and life expectancy of the PVDF coating for your chosen project so that you can be certain that your project will withstand hostile environmental conditions.

Final thoughts on the importance of sustainable and innovative building materials.

Building materials need to be durable, resistant, great performing, and decorative in order to meet environmental challenges. High-quality PVDF-coated ACP panels provide both a sustainable and innovative solution for achieving these objectives. With their superior performance, color retention, and durability, they are undoubtedly one of the most sought-after building products around the world. As climate change increases demand for higher-performing material solutions that can withstand extreme weather conditions and last longer, it’s important for designers and builders to consider the quality of their chosen materials before installing them.

In conclusion, PVDF-coated ACP panels are a great option for architects and builders when it comes to building quality, durable, and sustainable structures. With their superior performance, and resistance against heat, humidity, chemical substances, UV radiation, and more; they are undoubtedly one of the most sought-after building products around the world. When considering material options for a project, it’s important to consider all of the positive elements that PVDF coating offers ACP panels!

How we can help you?

At Rahul Arts India, we understand the importance of maintaining the appearance and functionality of your building. That’s why we offer PVDF ACP recoating / Aluminium Coating services to help businesses and individuals revive the look of their Aluminium Composite Panels (ACP). Our experienced team is equipped with the latest tools and techniques to provide a high-quality recoating service, that meets the specific needs of your building. Whether you’re looking to restore the appearance of an old or damaged ACP, change its color or finish, or simply improve its insulation properties, we can help. Our PVDF Aluminium recoating services are cost-effective, customizable, and designed to extend the life of your panel while also improving its appearance. We take pride in delivering exceptional results and ensuring customer satisfaction. With Rahul Arts India, you can rest assured that your building is in good hands.

Contact us today to learn more about our ACP recoating services and how we can help you bring new life to your building.