When you think of pipes, what comes to mind? Probably a long, dull tube used to carry water or gas, right? Hold on to your hats because HDPE pipes are about to blow your mind! High-density polyethylene (HDPE) pipes are some of the most versatile, durable, and eco-friendly pipes you’ll ever encounter. They’re used everywhere — from delivering clean drinking water to carrying industrial waste. But what exactly are the types of HDPE pipes? Let’s dive in and find out!

Types of HDPE Pipes

HDPE pipes come in various types, each with its specific use, depending on the job at hand. Let’s explore the different types of HDPE pipes and see why they’re so popular in the world of piping!

1. Type 1: HDPE Pipes for Water Supply

HDPE pipes are widely used in water supply systems. These pipes are designed to transport clean drinking water from one place to another without compromising the quality of the water. Thanks to their smooth interior surfaces, HDPE pipes reduce friction, which means water flows more efficiently, and there’s less chance for contaminants to cling to the pipe walls.

Why You’ll Love It:

- Smooth surface for better water flow

- Resistant to corrosion and scale buildup

- Long-lasting, even under pressure

- Ideal for both underground and above-ground installations

2. Type 2: HDPE Pipes for Gas Distribution

HDPE pipes are also a popular choice for distributing natural gas. Since these pipes are flexible and can withstand high-pressure systems, they’re perfect for delivering gas to homes and businesses. The best part? They’re resistant to cracking or bursting, so you can rest easy knowing your gas supply is secure.

Why You’ll Love It:

- Flexible and resistant to high-pressure

- Safe and durable for underground installations

- Less prone to cracking compared to metal pipes

- Cost-effective for large installations

3. Type 3: HDPE Pipes for Sewage and Drainage Systems

Another area where HDPE pipes shine is in sewage and drainage systems. These pipes are used to carry wastewater, stormwater, and other unwanted liquids. They are incredibly resistant to chemicals and other harmful substances, which means they won’t degrade or lose their strength over time. This makes them perfect for handling the nastiest of tasks (literally).

Why You’ll Love It:

- Resistant to chemicals and corrosion

- Highly durable in harsh conditions

- A smooth surface prevents clogs

- Suitable for underground installations

4. Type 4: HDPE Pipes for Industrial Use

HDPE pipes find extensive use across a wide range of industrial applications. These include transporting chemicals, slurries, and other substances that require specialized piping. Since HDPE is resistant to most chemicals, these pipes are perfect for industries that work with potentially hazardous materials. Consider them the uncelebrated champions of the manufacturing industry.

Why You’ll Love It:

- Resistant to chemicals, acids, and alkalis

- Flexible, making them easy to install

- Can handle high-temperature liquids

- Provides a longer lifespan compared to metal pipes

5. Type 5: HDPE Pipes for Irrigation Systems

Farmers and gardeners rejoice! HDPE pipes are also commonly used for irrigation purposes. These pipes can carry water to agricultural fields, gardens, and golf courses efficiently. Due to their flexibility, HDPE pipes are easy to install and can withstand the pressure of large irrigation systems. They are also resistant to UV rays, so they won’t degrade under the sun’s harsh rays.

Why You’ll Love It:

- Flexible and easy to install

- Resistant to UV damage

- Ideal for large-scale irrigation systems

- Durable and cost-effective for long-term use

6. Type 6: HDPE Pipes for Telecommunication and Electrical Ducting

HDPE pipes are not just for water, gas, or sewage. They’re also a great choice for protecting electrical cables and telecommunication lines. With their ability to withstand environmental stress and impact, they’re commonly used as conduits for fiber optic cables, electrical cables, and other communication lines. You’ve got to admit, these pipes have range!

Why You’ll Love It:

- Protects cables from physical damage

- Resistant to environmental stress and chemicals

- Flexible and easy to install

- Ideal for long-distance installations

7. Type 7: HDPE Pipes for Mining Applications

Mining operations often deal with harsh environments, extreme temperatures, and aggressive materials. HDPE pipes come in handy when it comes to transporting slurry, water, or chemicals from mining sites. These pipes are resistant to abrasion, which makes them a perfect choice for transporting the tough stuff that comes from mining.

Why You’ll Love It:

- Abrasion-resistant, ideal for mining applications

- Can transport slurry and other heavy materials

- Flexible and resistant to cracking

- Withstands harsh environmental conditions

8. Type 8: HDPE Pipes for Fire Fighting Systems

Did you know that HDPE pipes are also used in fire-fighting systems? These pipes are built to withstand extreme heat and pressure, which is exactly what you need in a fire emergency. They’re often used to carry water from the main source to hydrants or sprinklers, helping save lives and property when disaster strikes.

Why You’ll Love It:

- Resistant to high temperatures

- Long-lasting and durable

- Flexible, making installation easier

- Ideal for fire fighting systems in industrial or urban settings

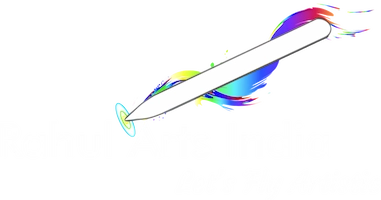

9. Type 9: HDPE Pipes for Undersea and Offshore Installations

HDPE pipes are not just confined to land-based applications. These pipes are also used in offshore and underwater installations. Their corrosion-resistant properties make them perfect for transporting oil, gas, or water in maritime environments. Whether it’s a deep-sea pipeline or an offshore oil rig, HDPE pipes have got you covered.

Why You’ll Love It:

- Resistant to corrosion from seawater

- Flexible for underwater installations

- Can handle extreme pressure and temperature

- Cost-effective for long-term offshore projects

10. Type 10: HDPE Pipes for Sustainable Construction Projects

With the growing focus on sustainability, HDPE pipes are increasingly being used in green construction projects. These pipes are not only eco-friendly but also durable, which makes them a popular choice for sustainable building practices. Whether it’s for stormwater management or recycling systems, HDPE pipes are a key component in making construction projects more eco-conscious.

Why You’ll Love It:

- Made from recyclable materials

- Durable and long-lasting

- Reduces the carbon footprint of construction projects

- Perfect for sustainable and green building projects

FAQs About HDPE Pipes

Q: Are HDPE pipes suitable for drinking water?

Yes, HDPE pipes are often used for potable water supply systems due to their non-toxic properties and resistance to contamination.

Q: Can HDPE pipes be used for both hot and cold water?

Yes, HDPE pipes can handle both hot and cold water applications, but their performance is best suited for cold water systems.

Q: How long do HDPE pipes last?

HDPE pipes are known for their longevity. They can last anywhere from 50 to 100 years, depending on the conditions and usage.

Q: Where can I get the best HDPE pipes?

Looking for high-quality HDPE pipes? Be sure to contact the best HDPE pipe provider for top-notch products and expert installation services.

Conclusion

So, there you have it! The types of HDPE pipes are vast and versatile, with each type serving a unique purpose. Whether you’re dealing with water supply, gas distribution, irrigation, or even industrial uses, HDPE pipes are the unsung heroes that keep the world running smoothly. Don’t forget to reach out to a trusted HDPE pipe provider for all your piping needs!

Remember, when it comes to choosing the right pipe for the job, HDPE pipes are the way to go for durability, flexibility, and cost-effectiveness!