If you’re looking for an overview of the chemical vapor deposition process, this post is for you. Dive in to learn about CVD and its phases!

Chemical vapor deposition (CVD) is a process used to produce high-quality, high-performance solid materials such as diamond-like coatings, nano-optics, and semiconductors. Learn more about its different phases, applications, and advantages of CVD here.

What Is Chemical Vapor Deposition (CVD)?

Chemical vapor deposition (CVD) is a process used to deposit thin films of various compositions of chemical products on a substrate. By controlling the composition, temperature, and pressure of the source gas materials, CVD enables the growth of solid crystals with precise characteristics. CVD has become an important tool for making thin films for semiconductor devices and microelectronics, and for applications such as device isolation and MEMS fabrication.

What Does a CVD Process Look Like?

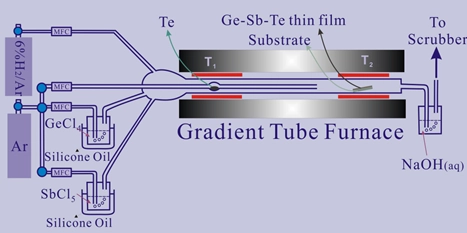

A typical CVD process consists of four main areas: the source gas, the substrate, the chamber, and the deposition chamber. During a CVD process, a purified source gas is introduced into a heated chamber, where it will react with other gases and/or radiation in order to deposit its desired material onto the substrate. The chamber is then pumped out to remove any excess reactants and products from the reaction. Finally, once all of these elements have been accounted for and balanced within the chamber, the deposition process can begin.

How Are Different Types of CVD Used?

Depending upon the desired material being deposited and the type of substrate being used, various types of CVD processes can be employed. For instance, low-pressure CVD (LPCVD) is typically used for depositing highly uniform film materials at temperatures below 1000°C. On the other hand, atmospheric-pressure CVD processes (APCVD), such as plasma-enhanced CVD, are useful when depositing materials that require higher chamber temperatures to decompose and activate their reactants. In either instance, a variety of input gases can be used in order to control the formation of different types of products.

What Are the Benefits of the CVD Process?

The CVD process provides a number of benefits compared to other types of deposition techniques. CVD films are well adhered to with controlled compositions, resulting in higher film quality and improved device performance. Additionally, CVD allows for the deposition of films on various substrate materials in a cost-effective manner and with a high degree of conformality. Finally, since it can be used at different temperatures and pressures, CVD is suitable for producing films with different properties depending on the application requirements.

What Considerations Should Go Into Preparing for CVD?

Before implementing the CVD process, it is essential to consider all potential issues that could arise. This includes an analysis of the substrate materials, type, and composition of the reaction gases, effects of processing temperature, selection of the optimal equipment parameters, etc. Additionally, CVD processes often require vacuum systems and inert atmospheres; specialized cleaning methods may also be necessary beforehand. Lastly, sample characterization techniques such as X-ray diffraction (XRD) should also be employed to help ensure a more accurate homogeneous deposition process.

Pingback: Aluminium Building Coating Options Available Today - RAI Blog